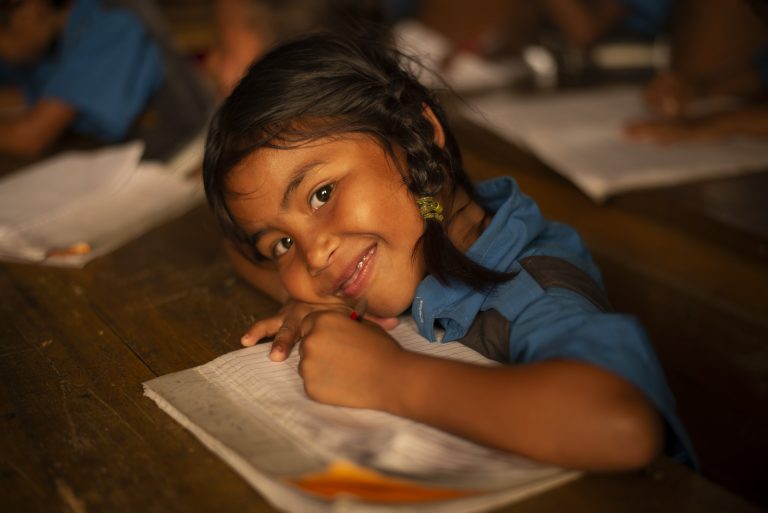

Quality of MDM

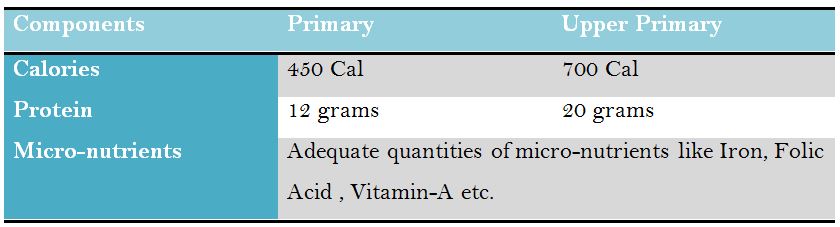

We have always strived to serve children to the best of our ability to ensure that they are not deprived of education because of hunger. Our mid-day meals are designed to meet the nutritional requirements recommended in MDM Guidelines, i.e., 450 Kcal and 12g protein for children studying in class I-V and 700 Kcal and 20g protein for children in class VI-VIII.

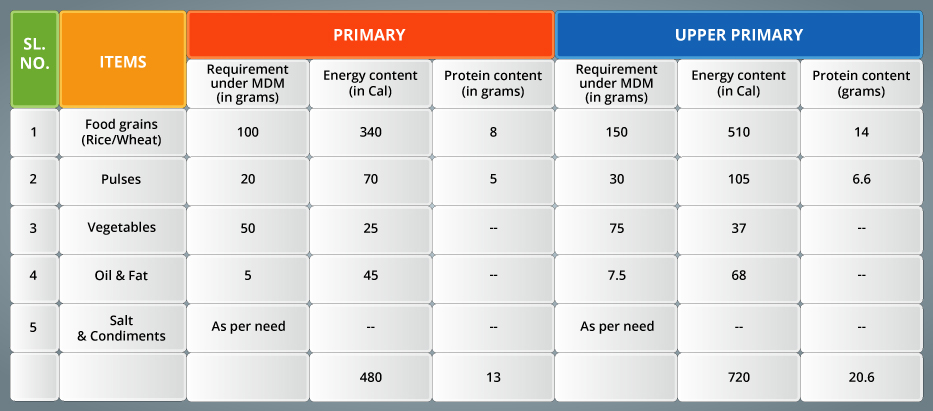

Prescribed MDM Nutritional Norms

The table below shows the item-wise dietary norms as stated by the Central Mid-Day Meal Scheme:

Our kitchens are Food Safety and Management System (FSMS), 5S (Sort, Straighten, Shine, Standardise, and Sustain) and GMP (Good Manufacturing Practice) compliant. Standardisation of recipes is an important factor for maintaining high levels of nutrition and taste. A well-structured quality assurance programme is implemented at all stages of operations—pre-production, production and post-production—to achieve this.

Quality assurance is a key process we have adopted to ensure the safety of food. Scientific control measures have been established, monitored and verified for all processes by the quality control and quality assurance teams. Quality inspections are undertaken at multiple points, right from the purchase of raw material to delivery of cooked food.

The quality of raw material is ensured by Supplier Quality Management System (SQMS). Suppliers are only approved after an audit at their manufacturing premises by the regional team to check for quality and food safety compliance. Raw materials are purchased only from approved suppliers. Raw materials are purchased only from approved suppliers. Raw material specifications are circulated to suppliers and they are thoroughly checked by kitchen quality team before accepting. If they are not meeting the FSSAI and AGMARK specifications, they are rejected. Received vegetables are sorted, washed and sanitised prior to use and stored in the cold storage.

All the kitchens have well-trained cooks and production supervisors to manage and oversee the process. Critical Control Points (CCPs), such as the cooking temperature, are checked and recorded at periodic intervals to ensure the right quality of meals. In order to ensure food quality is maintained, quality check is done by the quality officers in each kitchen. The quality team has all rights to hold and/or reject any process and products that do not adhere to requisite norms. Sensory evaluation is conducted by trained personnel before releasing the cooked food.

We have set up Food Safety and Quality Control (FSQC) labs to ensure the safety and quality of mid-day meals. These labs are equipped with the latest technology and high-precision testing instruments to facilitate the evaluation of products ranging from raw materials to cooked meals. The refractometer, for instance, helps in testing the total soluble solids, fat purity and adulteration in oils. Similarly, the Duran-make glassware and weighing scales with 0.0001 gm accuracy facilitate utmost accuracy when it comes to physical, chemical and microbiological analysis of food.

We also have New Product Development Centres (NPDCs) to add to the feasibility of making mid-day meals more nutritious by developing new recipes and opting for in-recipe modification.

We aim to bring positive changes in the nutritional habits of children, improve their concentration and eventually their academic performance.

Click here to know about our Food Safety and Quality Management practices.